A concrete batching plant, also known as a concrete mixing plant, is a facility where various ingredients are combined to produce ready-mix concrete. It consists of different components, including cement silos, aggregate bins, conveyors, mixers, and control systems. The primary function of a batching plant is to mix the ingredients in precise proportions to create high-quality concrete for construction purposes.

Ingredient Mixing and Proportioning

One of the key roles of a concrete batching plant is to ensure proper mixing and proportioning of the ingredients. This is achieved through advanced control systems that accurately measure and regulate the quantities of cement, aggregates, water, and additives required. By achieving the correct mix design, the batching plant produces consistent and reliable concrete that meets the project specifications.

Continuous Production Capability

Concrete batching plants are designed for continuous production, enabling a steady supply of fresh concrete. This is crucial when working with a concrete paving machine, as a constant flow of concrete is necessary to maintain efficiency and productivity. The batching plant can produce a large volume of concrete, ensuring a seamless supply to the paving machine without interruptions or delays.

Concrete Paving Machine

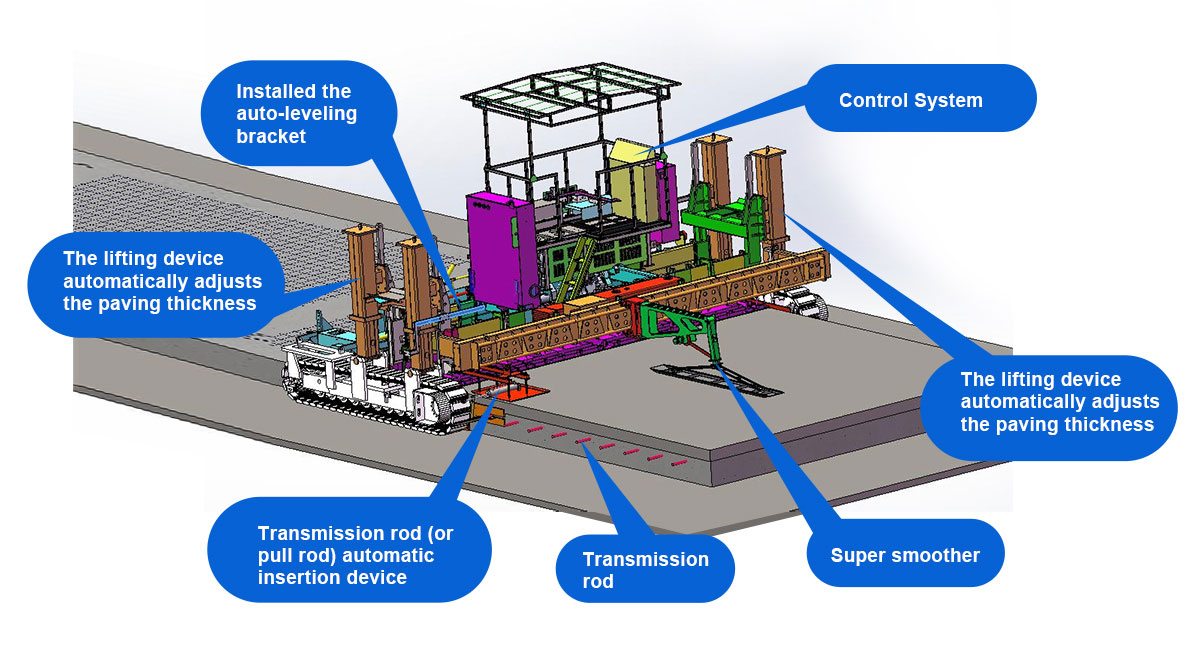

A concrete paving machine, or slipform paver, is a specialized construction equipment used to lay and shape concrete pavements with precision. It moves along the designated path while extruding and finishing the concrete in one continuous operation. The paving machine ensures a smooth and uniform surface, meeting the required thickness and dimensions for roads, highways, runways, and other paved areas.

Efficient Concrete Placement

The concrete paving machine works in conjunction with the concrete batching plant by receiving a constant supply of freshly mixed concrete. This eliminates the need for manual concrete placement and significantly enhances efficiency. The paving machine spreads the concrete evenly and accurately, ensuring consistent thickness and density throughout the pavement, resulting in a high-quality finished product.

Precise Shaping and Finishing

Concrete paving machines are equipped with sophisticated controls and sensors that enable precise shaping and finishing of the concrete pavement. They can adjust the speed and flow rate of concrete deposition, ensuring proper alignment and smooth transitions. The machines also incorporate finishing equipment like vibratory screeds or trowels to achieve the desired surface texture and compaction, enhancing the durability and aesthetics of the pavement.

Synergy between Batching Plant and Paving Machine

The relationship between a concrete batching plant and a concrete paving machine is symbiotic. The ready mix concrete plant for sale supplies a continuous stream of fresh concrete to the paving machine, ensuring uninterrupted workflow and optimal utilization of resources. The paving machine, in turn, relies on the batching plant to provide a consistent and customized concrete mix suitable for the specific project requirements.

The seamless coordination between these two equipment types minimizes downtime, reduces material waste, and improves overall productivity. It allows for efficient execution of large-scale concrete paving projects, meeting stringent quality standards and deadlines.

The relationship between a concrete batching plant and a concrete paving machine is crucial in the construction industry. The batching plant provides a steady supply of high-quality concrete, while the paving machine efficiently places and shapes the concrete to create durable and reliable pavements. Together, they enable the successful completion of complex infrastructure projects, ensuring safe and smooth transportation networks for years to come.